Case04

Improving cleaning quality without investment in pallet washing equipment

Pallet Washing Services

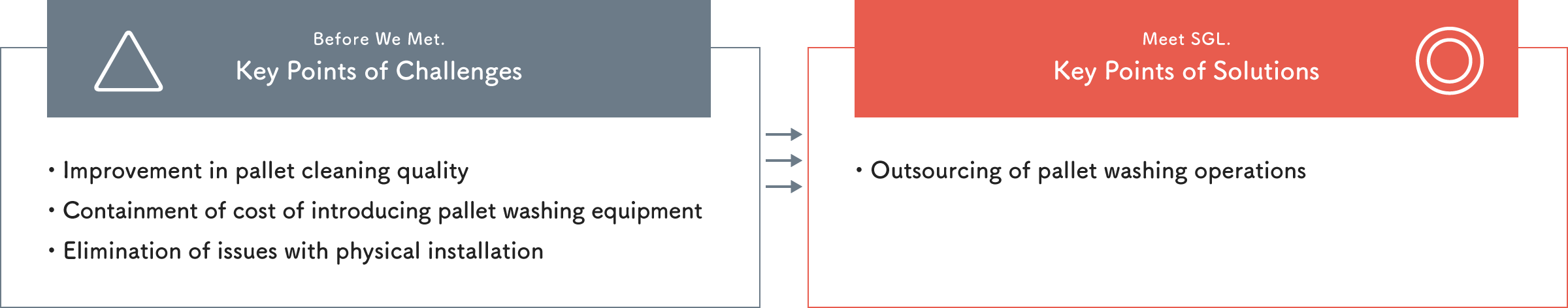

Company C, a pharmaceuticals manufacturer, uses its own pallets for product shipments. The number of pallets it owns has increased over the years in line with the growth in its shipment volume.

Collected pallets had been cleaned manually by Company C in house.

Given heightened sanitation and quality standards such as GMP* in recent years, Company C had been requested by customers to improve pallet sanitation and foreign material contamination countermeasures, and as such was considering the installation of pallet washing equipment.

However, in addition to the high amount of capital expenditure, this posed many other challenges such as expansion of the factory site to accommodate the installation of the equipment and running costs such as utilities and equipment maintenance.

*GMP in the pharmaceuticals industry: “Regulations for the Manufacturing Control and Quality Control of Pharmaceuticals”

By outsourcing pallet washing to SGL, Company C was able to realize high quality washing using automatic washing equipment and circumvent large investment.

SGL inspects all pallets upon receipt and sorts them according to how damaged or soiled they are.

Not only do we subject the pallets to optimal additional cleaning according to the degree of soiling, but we also store them in a high-floor warehouses that have been designed to prevent insects and the like from contaminating the pallets. This has also enabled us to maintain the sanitation quality of the pallets after they have been washed.

Some stains are difficult to remove by hand washing, and the workload is heavy

Outsourcing makes machine-washing possible while keeping costs down

- ● Service that resolved this challenge: Pallet Washing Services

- ● Client business category: Pharmaceuticals manufacturing business