Case03

Offering consistent entrustment of procurement and logistics management

Project Transport

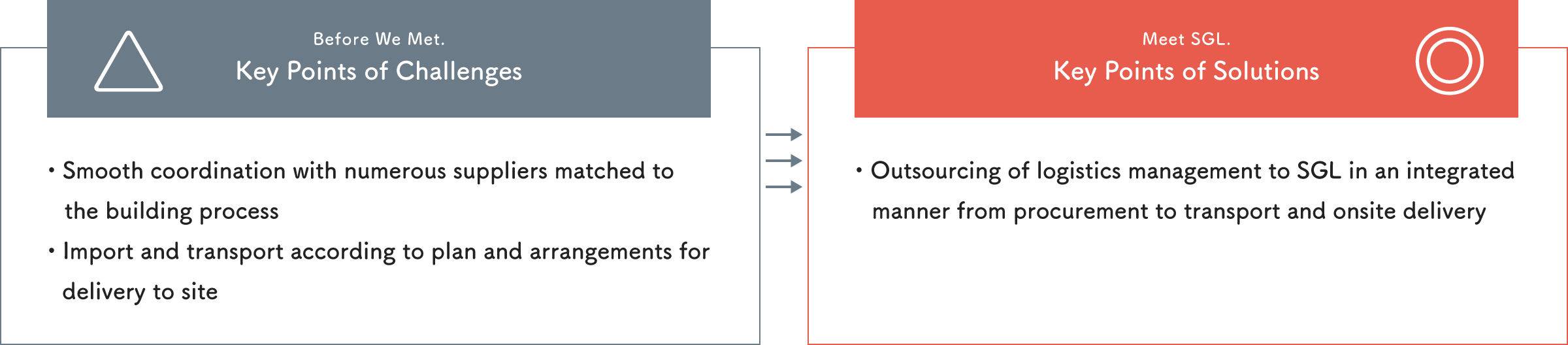

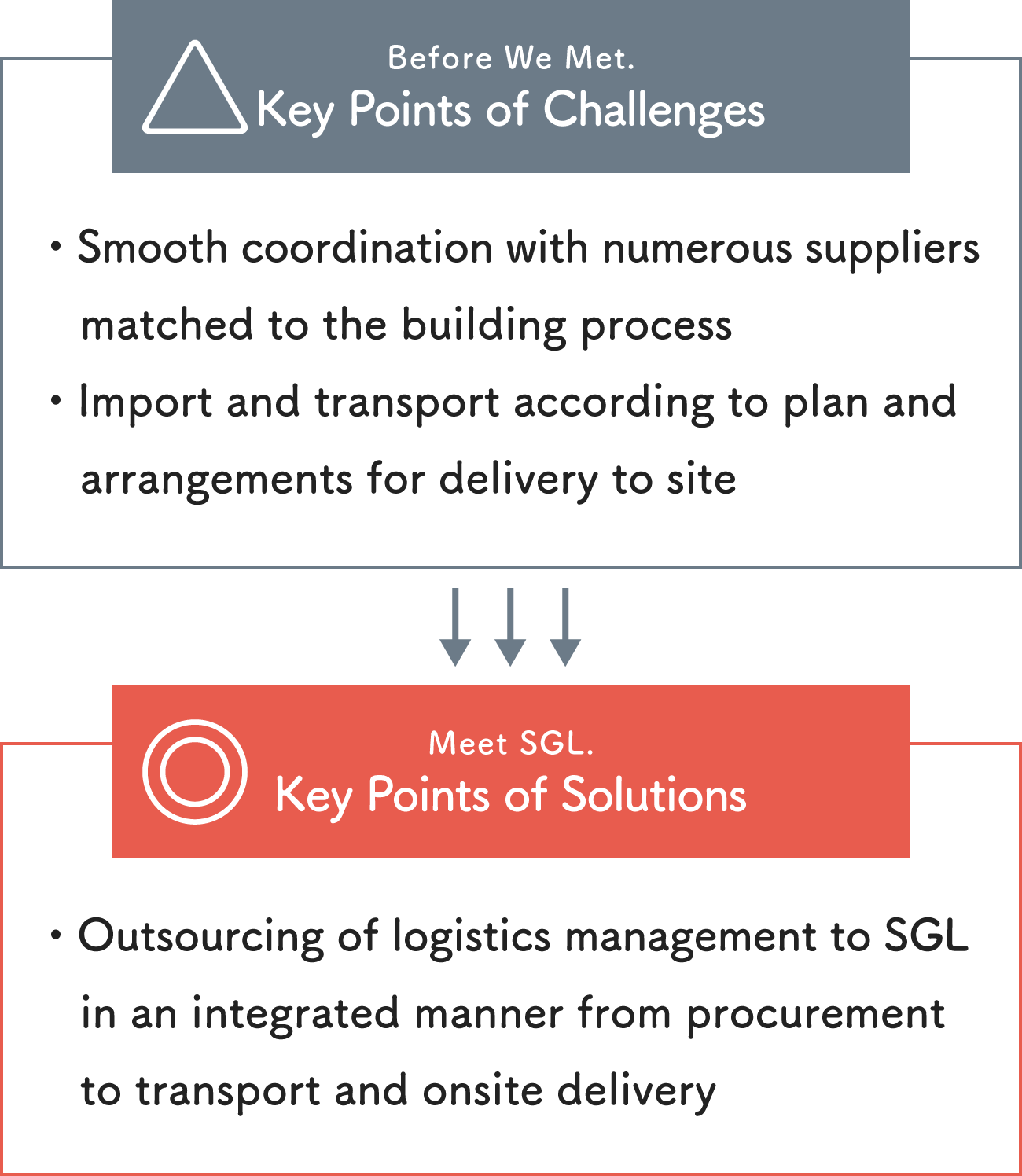

Company C needed to procure and manage as much as 10 million necessary parts and materials from roughly 200 suppliers spread across 25 countries, mainly in Europe, for the building of a luxury cruise ship.

Because the warehouse at the building site had space limitations, making long-term storage difficult, it was necessary to deliver parts and materials in line with the building process. However, due to the sheer number of suppliers, parts and materials, managing shipments, inventory and carry-in was massively difficult.

Because SGL undertook procurement and logistics management on an integrated basis, the contact points for logistics were centralized. This eliminated the prior need for the complicated communication and arrangement work for logistics cycles, which Company C had perceived to be an issue.

We coordinated shipments with each supplier and managed timely shipments in accordance with vessel schedules.

We ascertained and managed the status of shipments, which had previously lacked transparency, and made full use of various means of transport to realize imports at the proper timing based on shipment timing and the building process.

Moreover, by visualizing inventory through the introduction of a system as well as reinforcing coordination with the building site, and erecting a mechanism that enables the timely delivery of parts and materials when they needed, SGL supported Company C's luxury cruise ship building project.

A major project to build a luxury cruise ship.

Procurement of parts and materials from roughly 200 suppliers spread across 25 countries, mainly in Europe

- ● Service that resolved this challenge: Project Transport

- ● Client business category: Heavy industry manufacturer