Case01

Reducing delivery lead times through local bonded inventory

Overseas Warehousing

Company B conducts exports of machinery and equipment to China. Until now, after receiving orders from customers, it would install accessories at its Japanese factory, then ship the equipment.

The problem with this was that installation work was performed after orders were received and shipments were made from Japan, disparity arose with competing domestic Chinese manufacturers in terms of lead time until delivery to the customer.

To compete with those competitors, Company B required a way to shorten the number of days from order receipt to delivery.

Additionally, with each order received, even those in a small quantity, export from Japan was needed, resulting in comparatively high transport costs.

By holding inventory in China, we succeeded in significantly reducing lead time following order receipt, enabling Company B to compete on the same playing field as its Chinese competitors.

Where export packaging and shipping arrangements also used to take time following order receipt, conducting shipping from Japan in advance has worked to streamline overall lead times from the receipt of orders to delivery.

Moreover, where Company B was previously forced to ship even small quantities with each order received, it can now export multiple units of equipment simultaneously, resulting in a considerable improvement in transport efficiency.

Furthermore, this has also led to inventory reductions on the Japanese factory side.

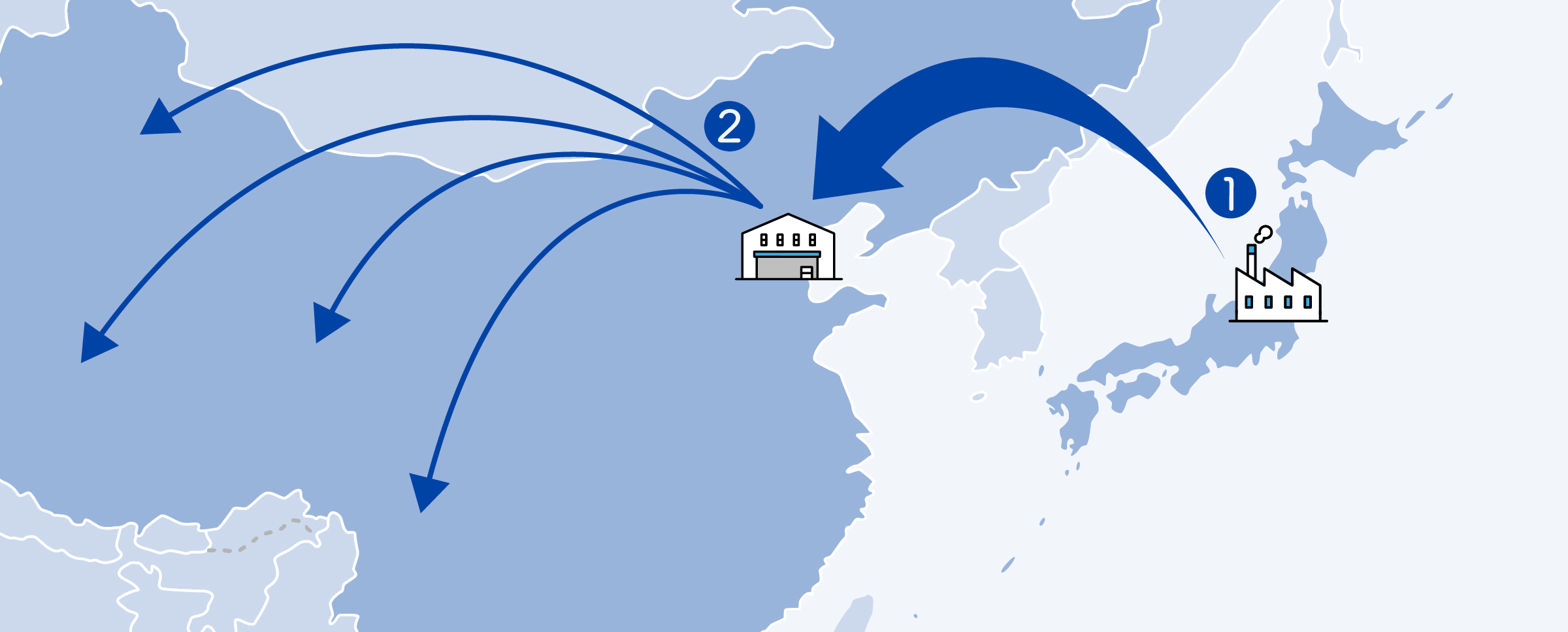

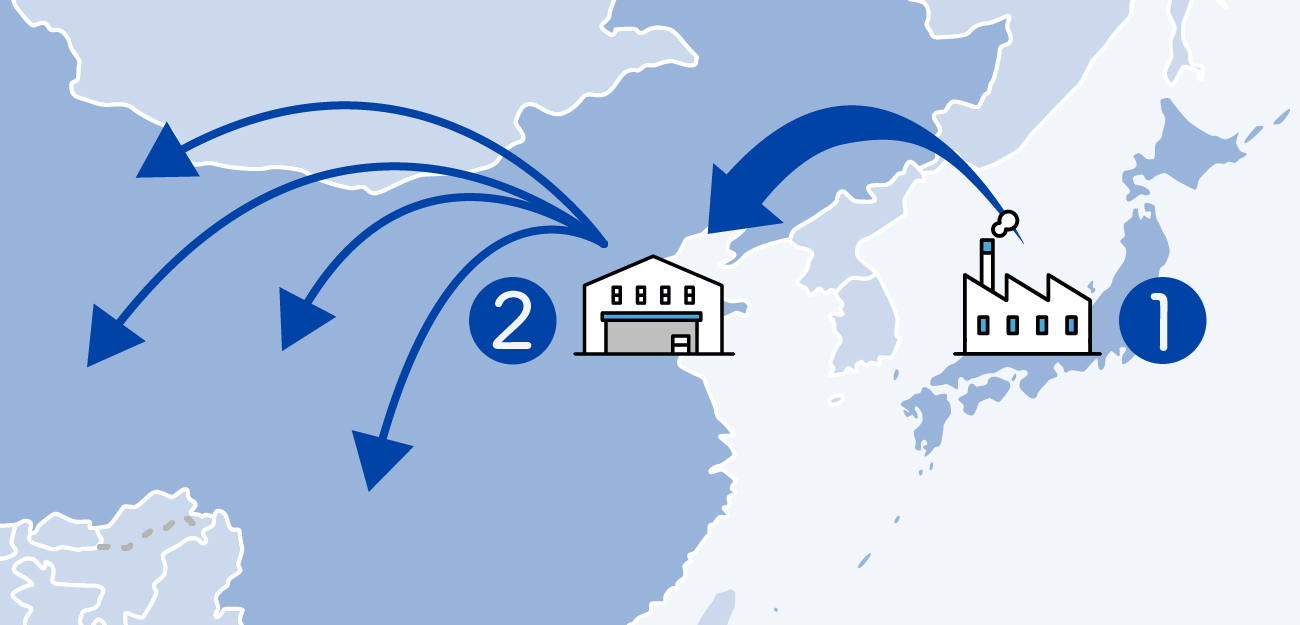

(1) Exporting from Japan in advance. (2) Conducting timely delivery to various locations in China following order receipt.

- ● Service that resolved this challenge: Overseas Warehousing

- ● Client business category: Industrial equipment manufacturer