Case03

Improving sanitation levels and reducing cleaning work

Liquid transport using MAXICON

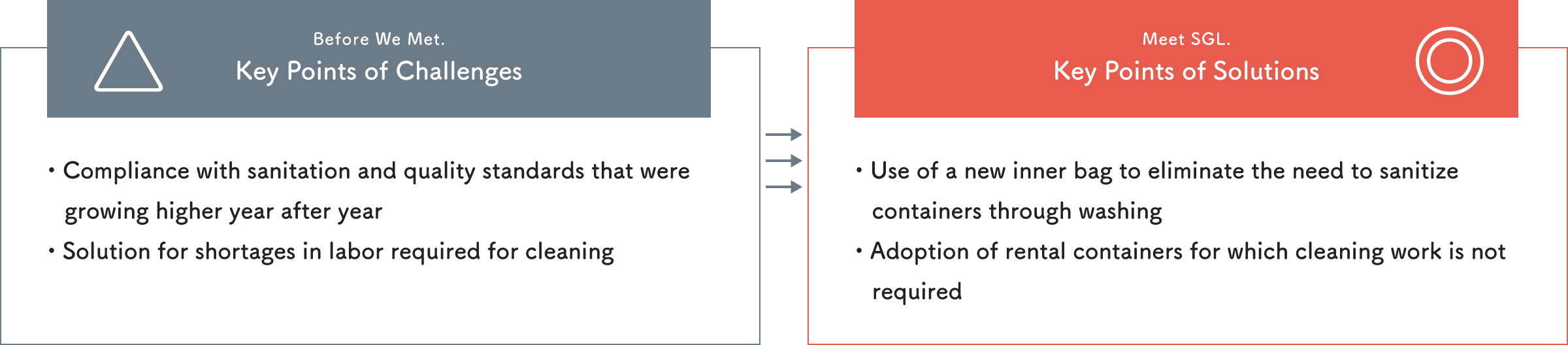

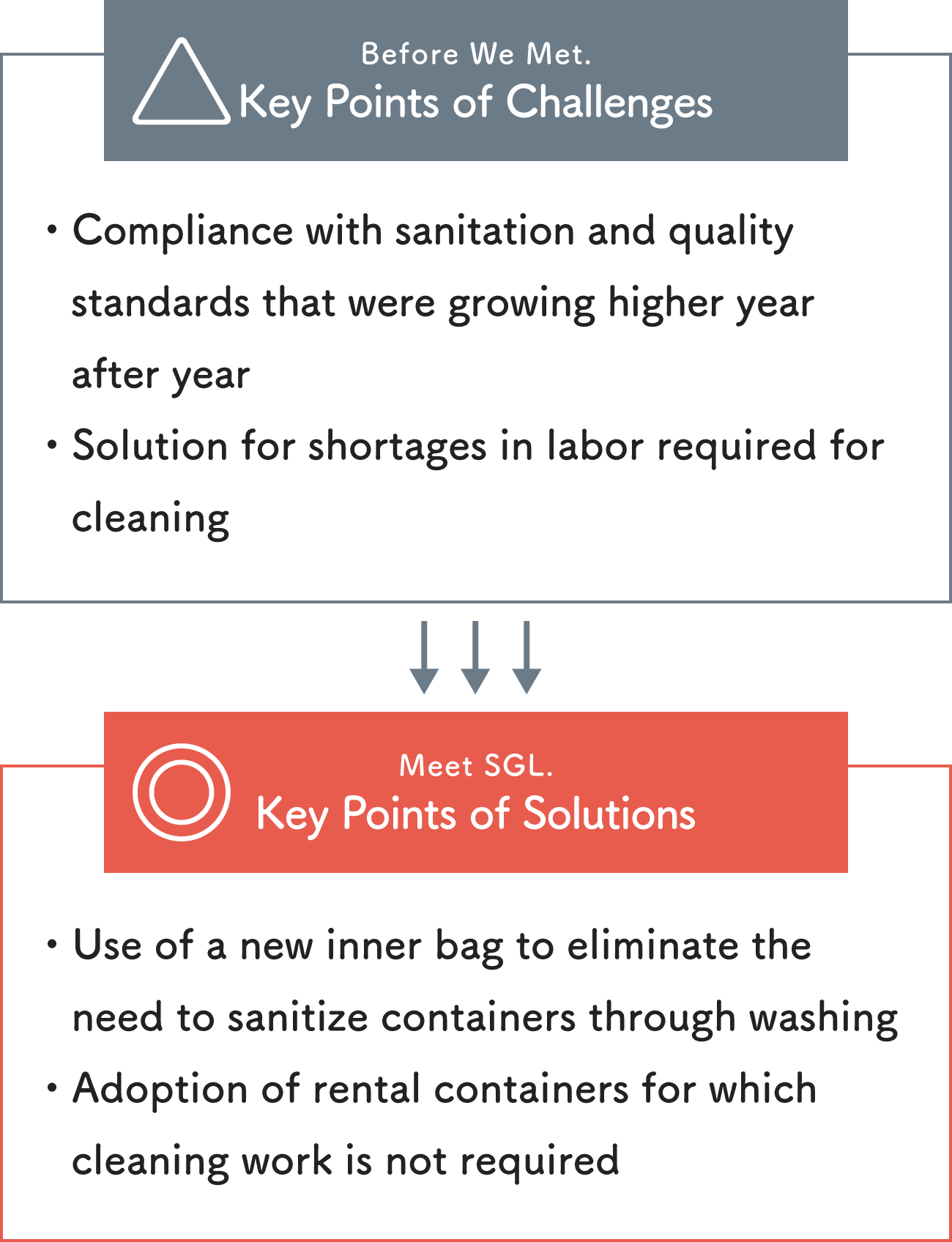

In line with heightened sanitation and quality standards such as GMP* in recent years, Company C reviewed its in-house container cleaning process.

While limited staff had been able to make ends meet, an increase in cleaning time due to an increased number of cleaning locations and processes was placing an ever-increasing burden on the site.

*GMP in the pharmaceuticals industry: “Regulations for the Manufacturing Control and Quality Control of Pharmaceuticals”

By adopting MAXICON and using a new inner bag each time, Company C brought about reductions in the risk of contamination by foreign matter or bacteria resulting from the likes of poor cleaning.

Moreover, since the containers were already cleaned and maintained at the service center, Company C was able to reduce personnel costs pertaining to cleaning work as well as utility costs such as detergent and water.

Sanitation is also assured with the use of a new inner bag each time

Containers are cleaned and maintained at the service center

- ● Service that resolved this challenge:Logistics Container Rental

- ● Client business category: Cosmetics Manufacturer