Procurement Logistics

Providing integrated merchandise procurement and supply services with the functions of a trading company

We’re SGL.

Based on the experience in logistics it has accumulated over many years, SGL provides integrated merchandise procurement and supply services that are also infused with the functions of a trading company.

Examples of Services

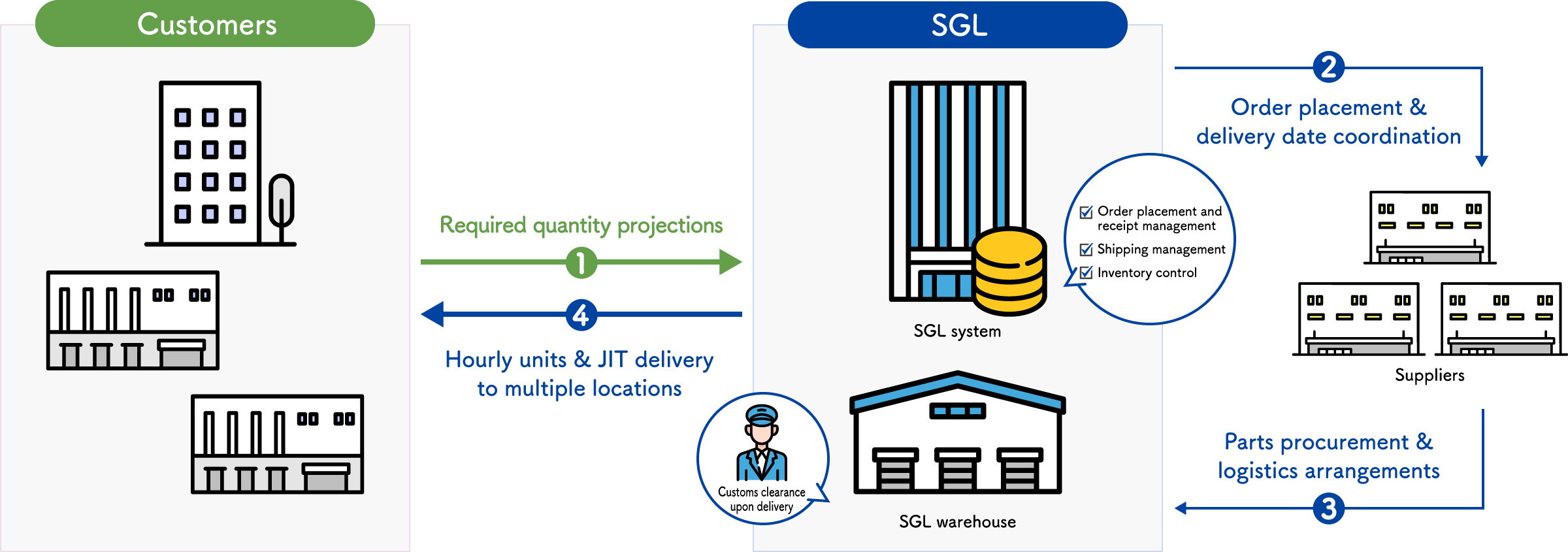

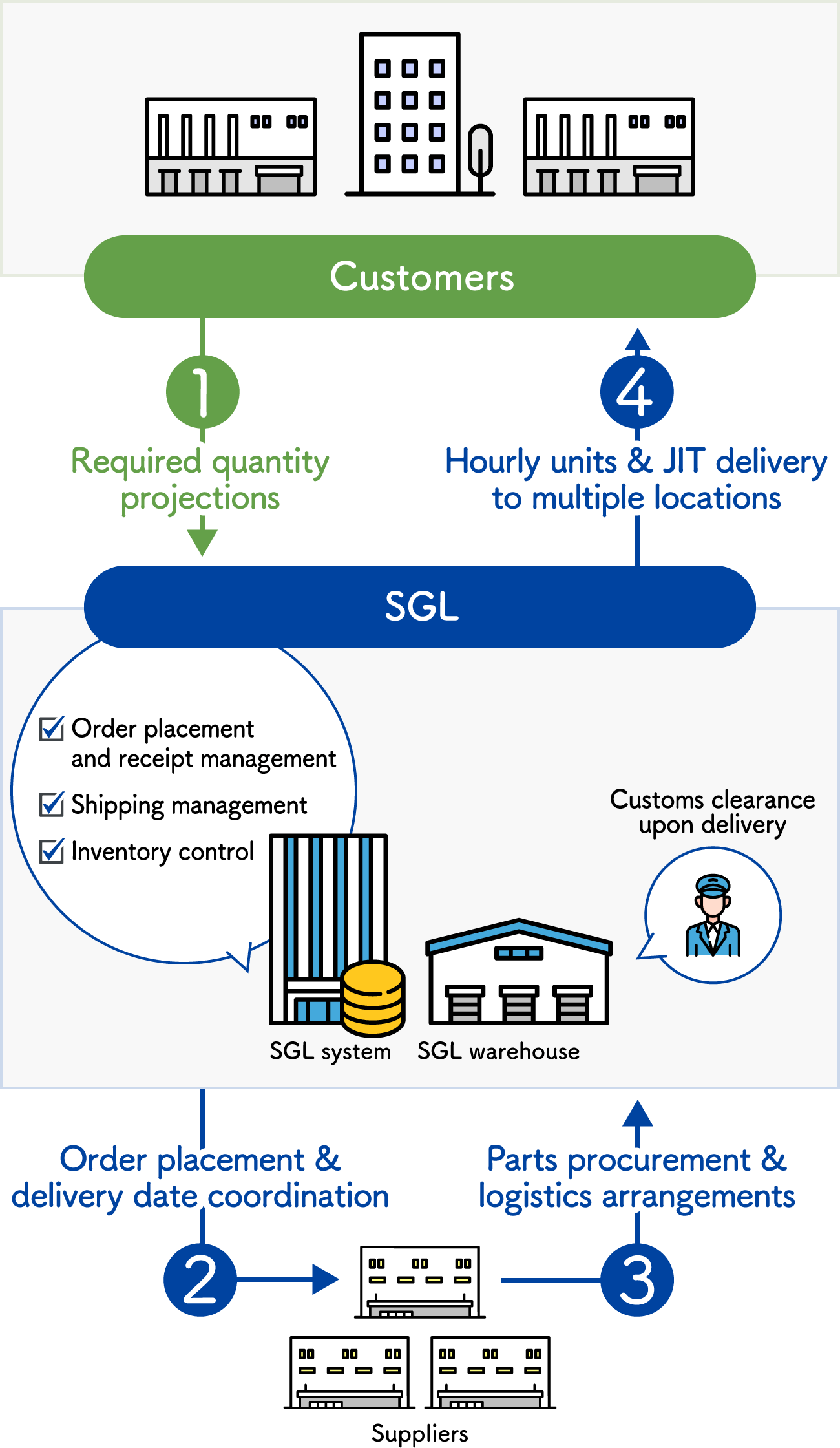

SGL undertakes the entire commercial and logistics process from procurement to delivery for parts and semi-finished products used by its customers in their production efforts.

We are also involved in parts procurement channels, acting as an agent for order placement and receipt operations, holding inventory in local bonded warehouses and implementing just-in-time delivery in accordance with production plans.

Based on KPI analysis and inventory simulations, we also work to optimize inventory and transport.

- 1We ask customers to notify us periodically of their required quantity projections and production plans.

- 2Based on the information we receive, we place orders in our name, taking into consideration suppliers’ production lead times and appropriate safety stock periods.

- 3We coordinate delivery dates with suppliers and verify shipments as well as handle logistics arrangements and import and export procedures.

- 4 After parts and semi-finished products arrive at our warehouses, we store them for a certain period of time and deliver what is needed when it is needed on a just-in-time basis.

Advantages of integrated merchandise procurement logistics

Improved cash flow

In cases involving direct procurement from suppliers, there is a gap in settlement timing between the procurement of parts and the sale of finished products, which tends to create a “cash short fall.”

By entering procurement channels, SGL procures parts just prior to production, resulting in settlement being made on a delivery date basis. This links to the improved cash flow of our customers.

Minimization of in-house inventory volume and control

SGL takes parts and semi-finished products that customers previously stocked in-house, including those stocked during safety stock periods, and stores them externally under its name.

This makes it possible to effectively use factory sites and save labor spent on inventorying and other inventory control operation, and also links to improvements in customers’ balance sheet.

Focus on core operations

By outsourcing operations pertaining to procurement such as detailed order placement and receipt and logistics arrangements, customers can concentrate their management resources on their core operations such as manufacturing.

International Logistics

International Logistics International Multimodal Transport

International Multimodal Transport